How it works

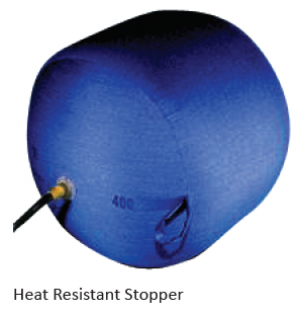

The Purge Bag Systems in the range manufactured by PPM are designed around the principle of using 2 dams to create a seal either side of the weld, just far enough away from the weld not to be effected by heat but close enough to the joint to provide the fastest weld purge time. These dams are connected by an armoured spinal tube.

Once ready to start purging, the system is inserted into the bore of the pipe using the luminous strip to centre the system to the weld gap.

When the gas flow is started, the dams inflate and, upon reaching the pre-set pressure, the valve releases the gas gently into the weld chamber, to purge the interspace without turbulence. The Oxygen is removed from the weld chamber through the integral exhaust tubes in the bags. Used in conjunction with PPM’s Oxygen Monitors to indicate when the required low level of oxygen has been reached, welding can then co mmence, with the inert gas enabling the welder to produce an even oxidation free penetration weld bead. Afterwards, the dams are deflated simply by disconnecting the purge gas feed and the system easily withdrawn. The design of these systems means that only one gas connection is required for both dam inflation and weld purging.

Add to Quote

Add to Quote