Surface combustion unit

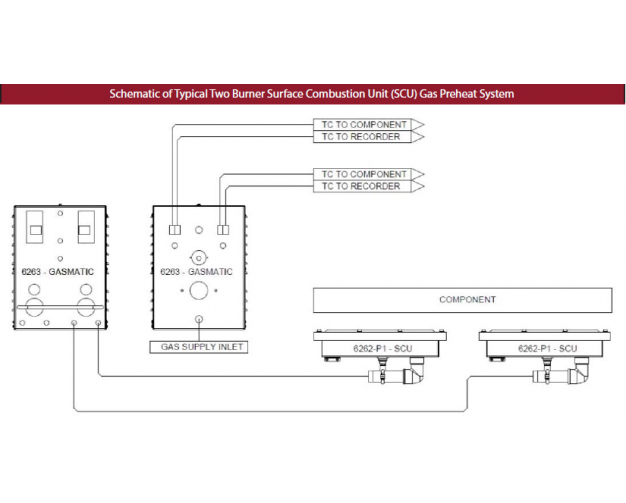

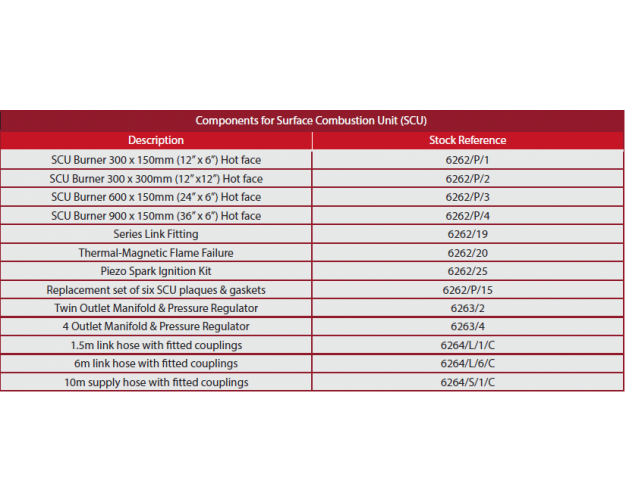

"STORK" SURFACE COMBUSTION UNIT (SCU)The Cooperheat Surface Combustion Unit (SCU) is an economical and highly efficient infra-red gas radiant heater that provides a radiant heat source for pre-heating metal fabrications. The SCU is available in a range of sizes.

Applications- Pre heat of rotating circumferential seams on fabrications,vessels and storage tanks etc, using floor mounted stands.

- Preheat of longitudinal welded seams.

- Preheat of sections of fabrications, vessels and storage tanks etc, requiring repair.

- Preheat of castings.

- Expansion of rotor rings for removal.

Infra-red energy is radiated by the hot face of the SCU.Liquefied Petroleum Gas (LPG) or high pressure natural gas enters the rear of the unit drawing in air, mixing inside the plenum chamber and then burns efficiently on the front face of the perforated ceramic tiles. Complete combustion is achieved without flaming. Compared with open flame gas burners, the SCU can save one-third or more of the gas input as there is the absence of flame management. The simplest setup involves one burner connected to a bottle of propane and positioned near the work piece at a distance of 50mm. An optional piezoelectric device can be used to ignite the gas-air mixture on the burner. Other burners may be added to the circuit by means of rapid connect / disconnect couplings. Revolving seams may be temperature controlled using an optical pyrometer and a control unit.

Add to Quote

Add to Quote